About The Products

To operate efficiently VRF or VRV* systems are operating at significantly higher pressures than we are used to seeing with Hydronic systems. Test pressures can reach 700 psi with 200F to 300F operating temperatures. These systems are operating at the high end of your piping components and as such are introducing stress levels that need additional design consideration.

The VRF Expansion joints, Seismic expansion joints and Flex connectors from Metraflex are designed specifically to compensate for these additional loads and stresses.

*VRV is a trademark of Daiken Industries, LTD

Which Is The Right Choice For Your Needs?

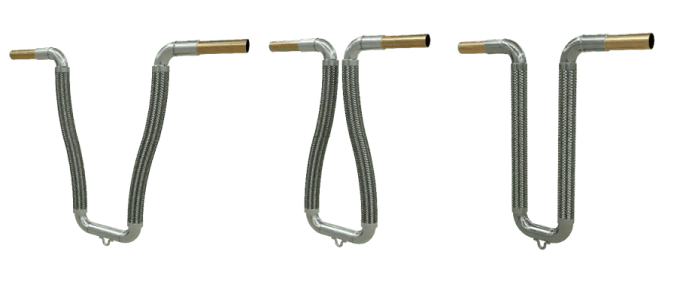

The Metraloop® U-bend geometry should be your first choice in design for compensating for thermal or seismic expansion. If you have the space perpendicular to the run of your pipe, having the flexible legs absorb movements laterally is the most efficient use of the flexible sections. If space is an issue explore the other configurations. The stocked VRF Metraloop® is designed for ± 4 inches of movement and 700 PSI at 250°F operating. Larger movements are available. Cold springing during installation is recommended.

V-Loop ± 4inch of movement and 700PSI at 250°F. It has a shorter perpendicular dimension from the pipe run. However more care must be given at installation as the 90° elbow between the two flexible legs will move more than the Metraloop®. The elbow must not be restricted from moving as this will impair the freedom of the flexible leg to absorb the thermal or seismic expansion.

The Dog Leg ± 4inch of movement and 700PSI at 250°F. This configuration is very efficient when installed at the intersection of two pipe runs. Considerations must be made to allow the 90 degree elbow to move.

The VRF Flex is only capable of lateral movement. This connector designed for vibration isolation and stress relief in the piping system. Operating at 700 PSI, many fittings in VRF systems are operating at or close to their maximum pressures. Pressurization may compound any installed residual stress. This may show up in unexpected fitting leaks. The VRF Flex can help minimize this situation.

Frequently Asked Questions

At these pressures, the VRF flexible loop becomes stiffer than loops operating at the max 200PSI we see in most HVAC systems. The longer legs are engineered to minimize anchor loading.

Bronze hose and braid is not strong enough for the pressures.

Cold springing is another way to minimize anchor loads. When the loop moves toward its neutral position, it is imposing no anchor loads.