Download PDF >

INTRODUCTION

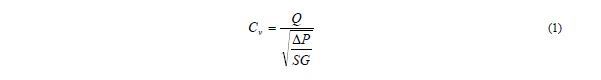

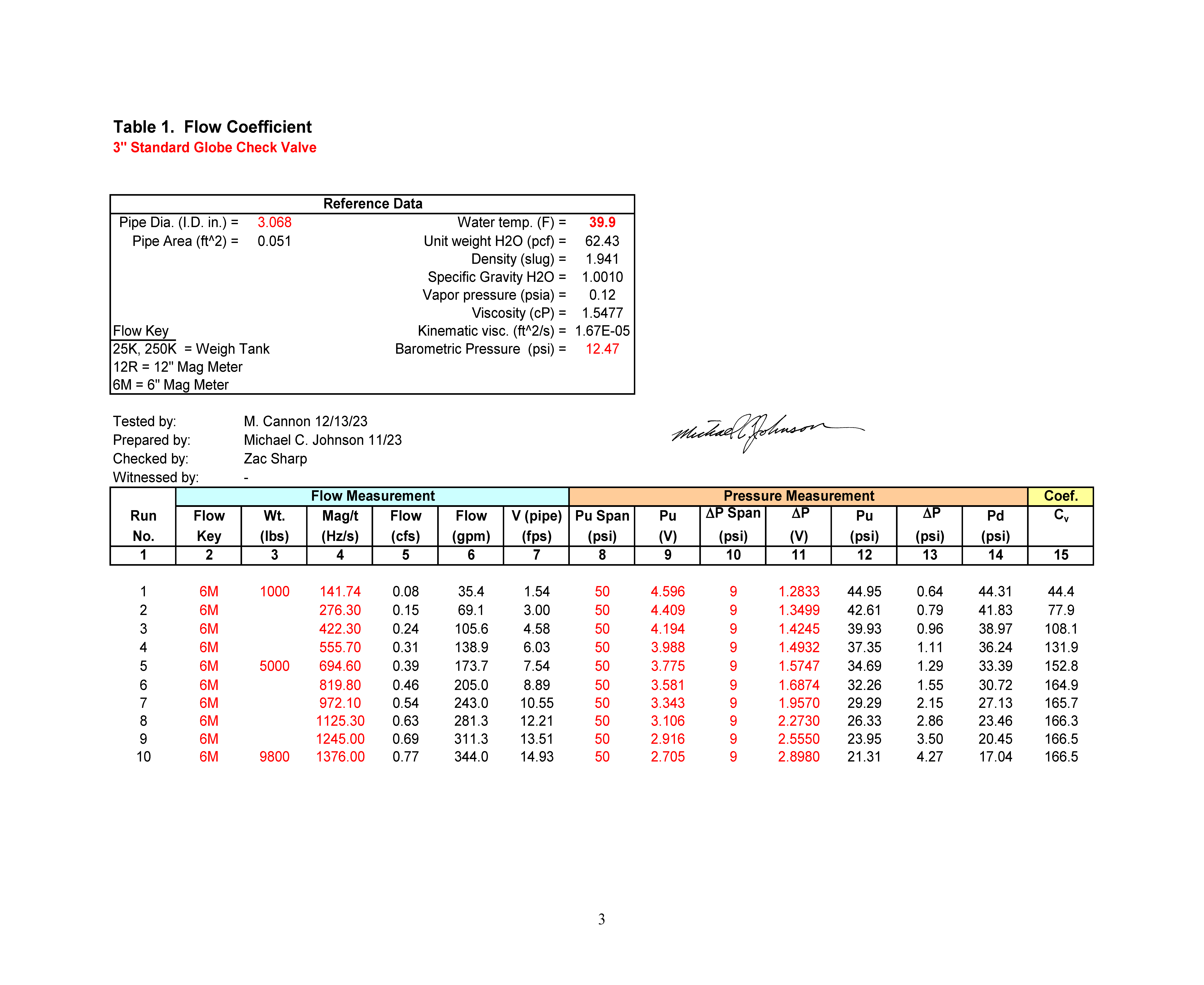

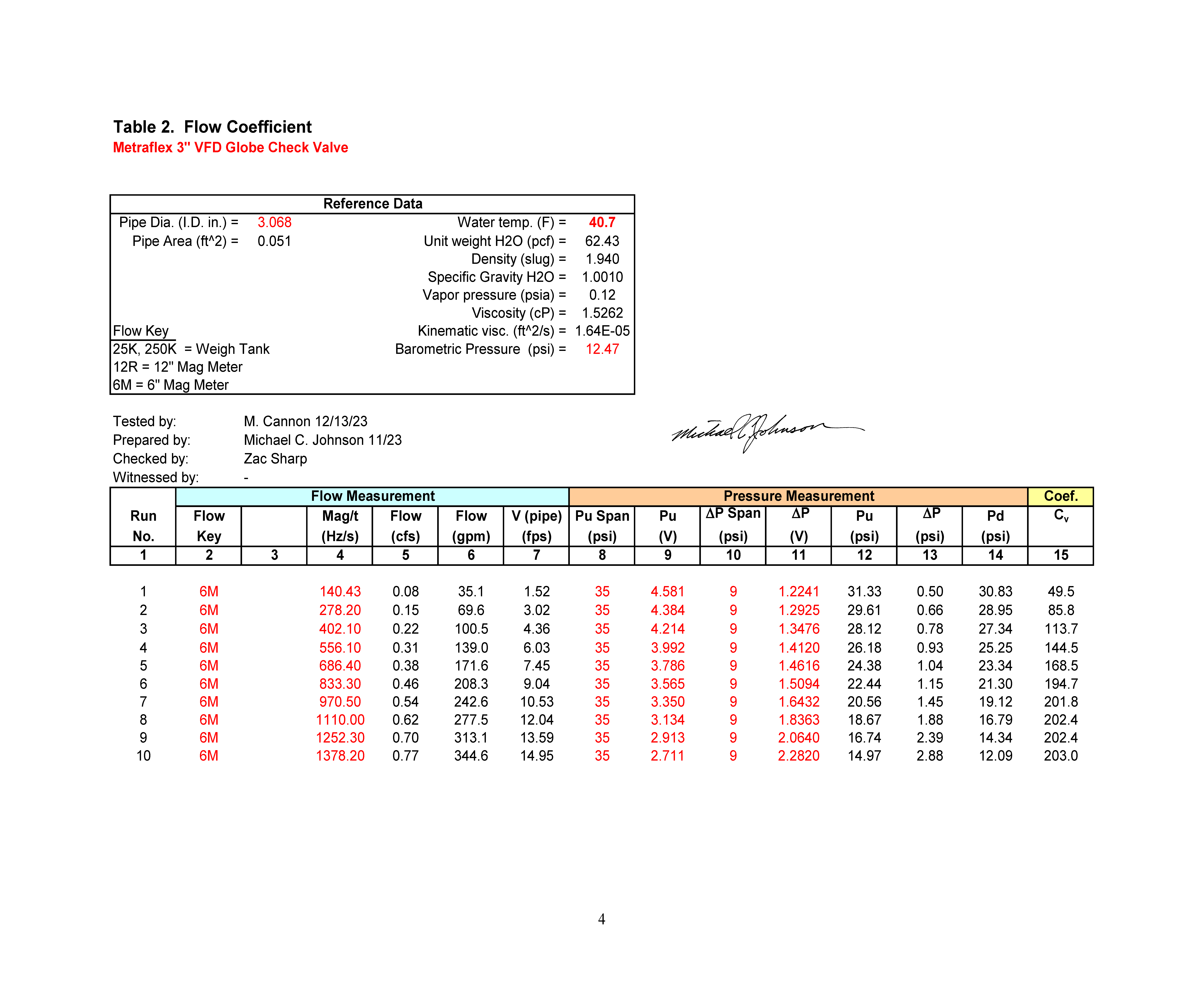

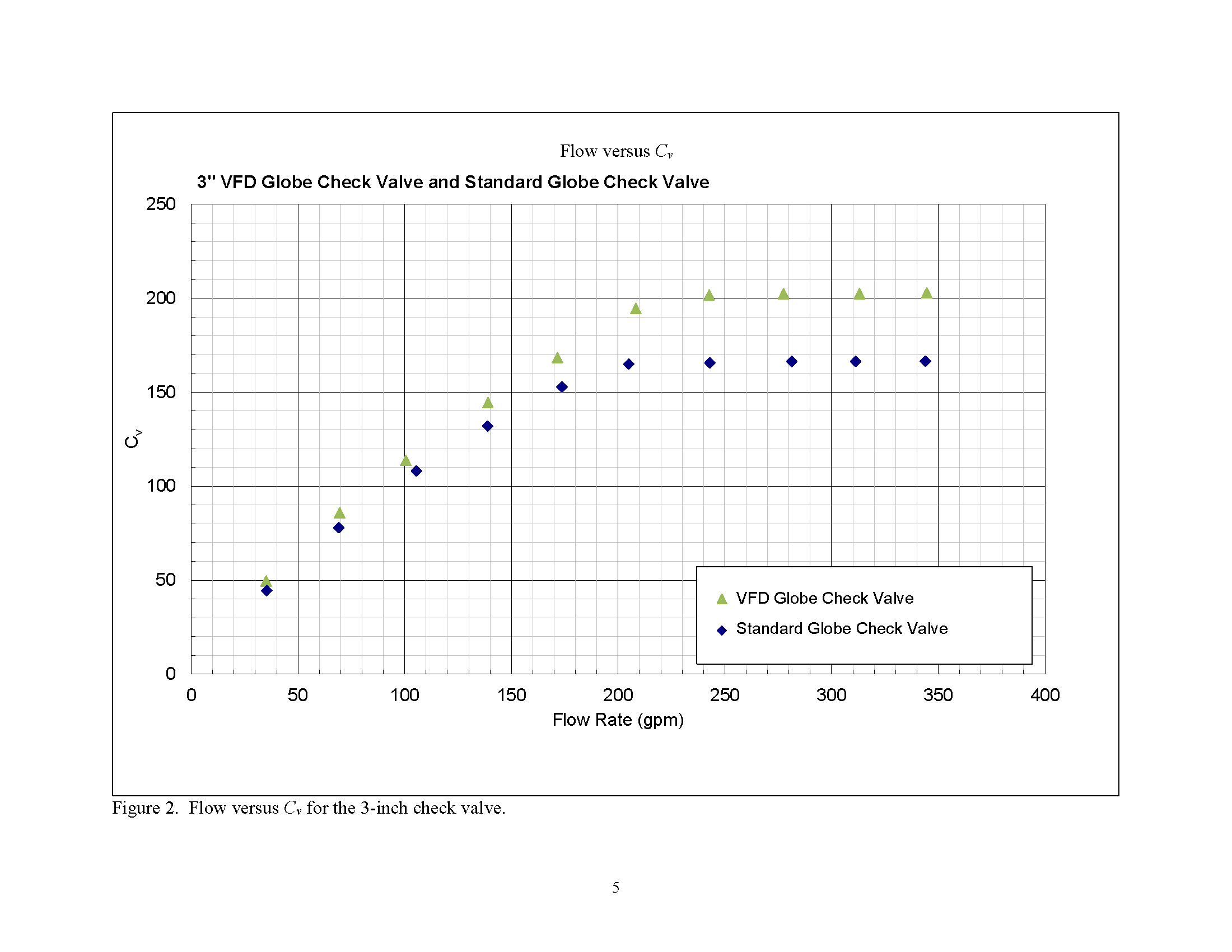

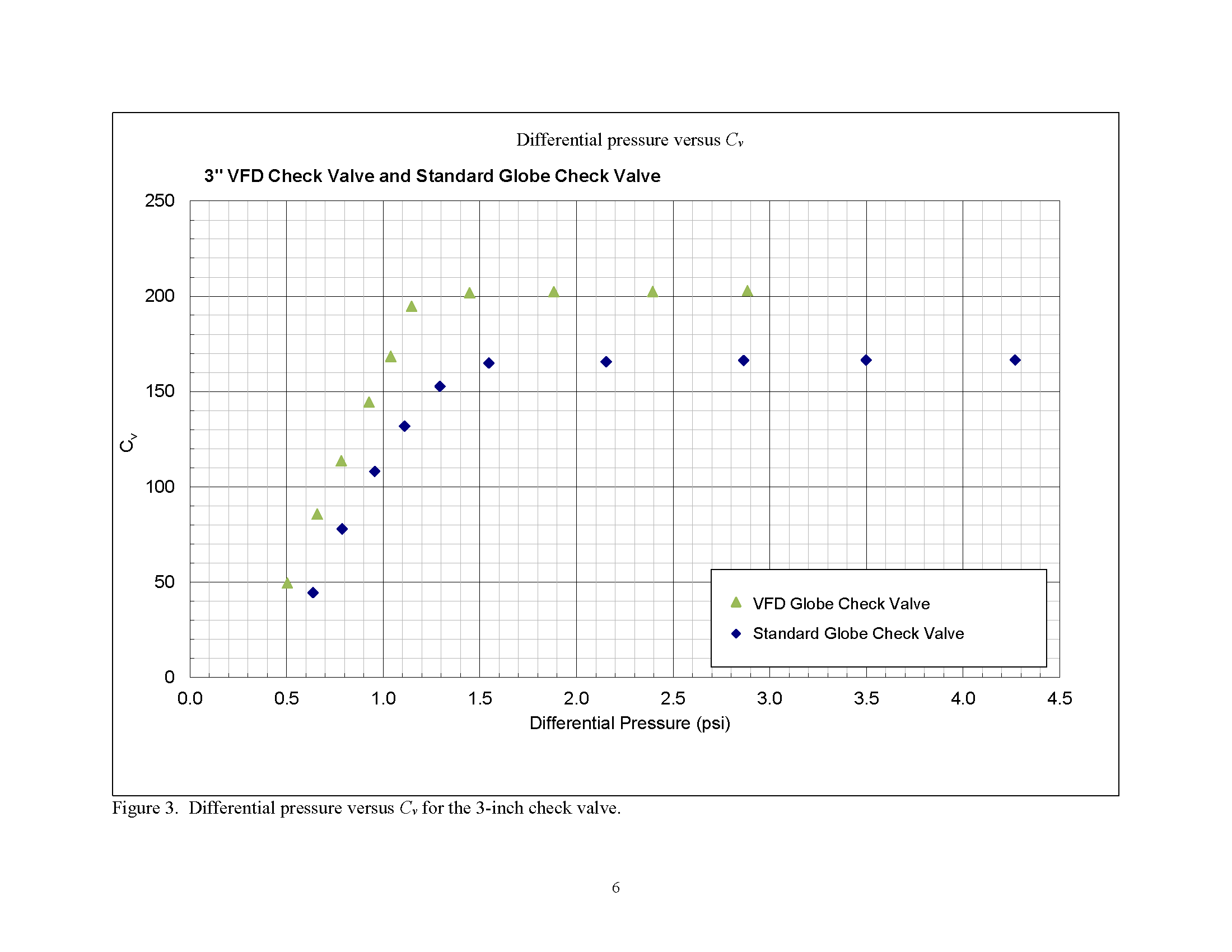

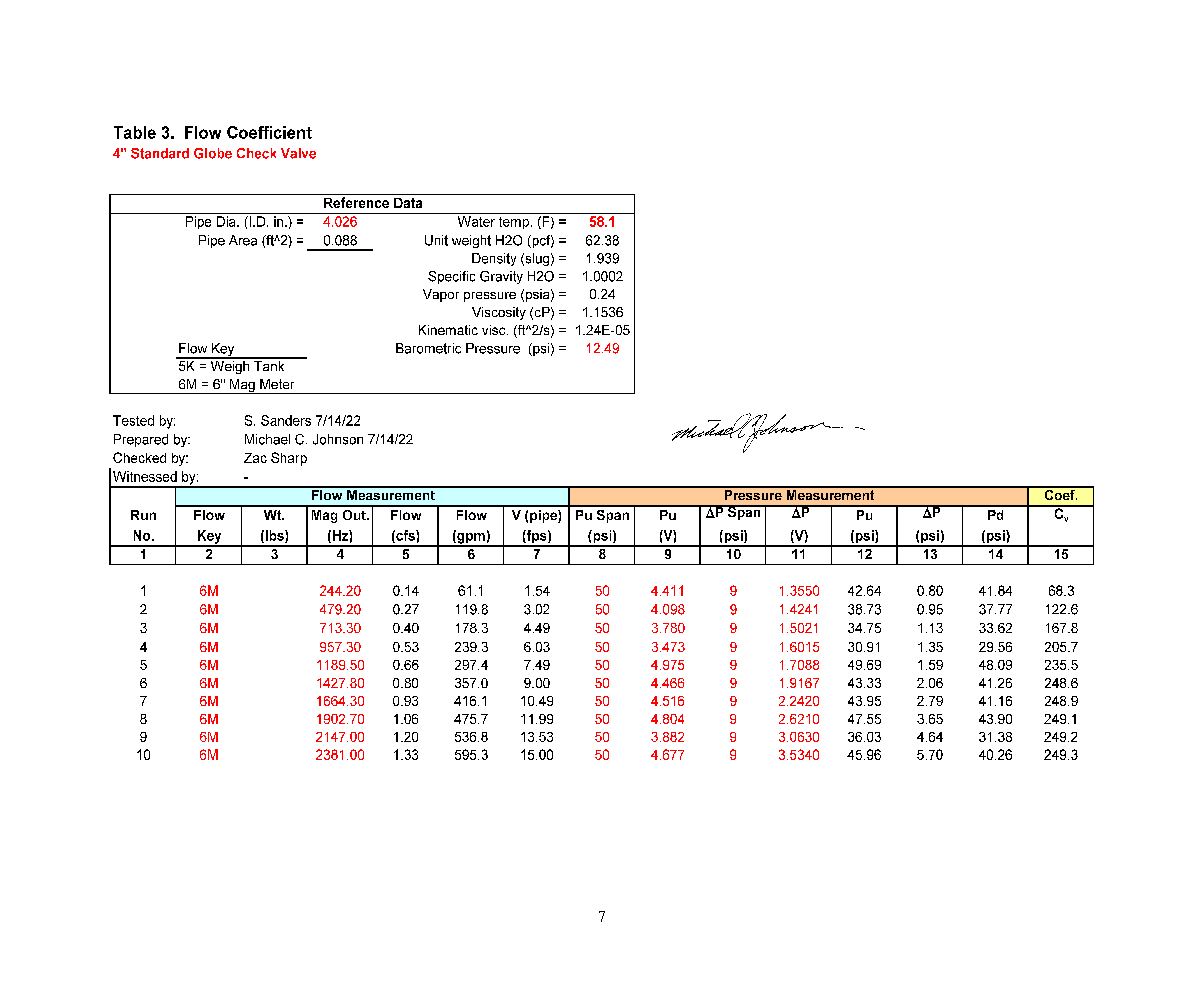

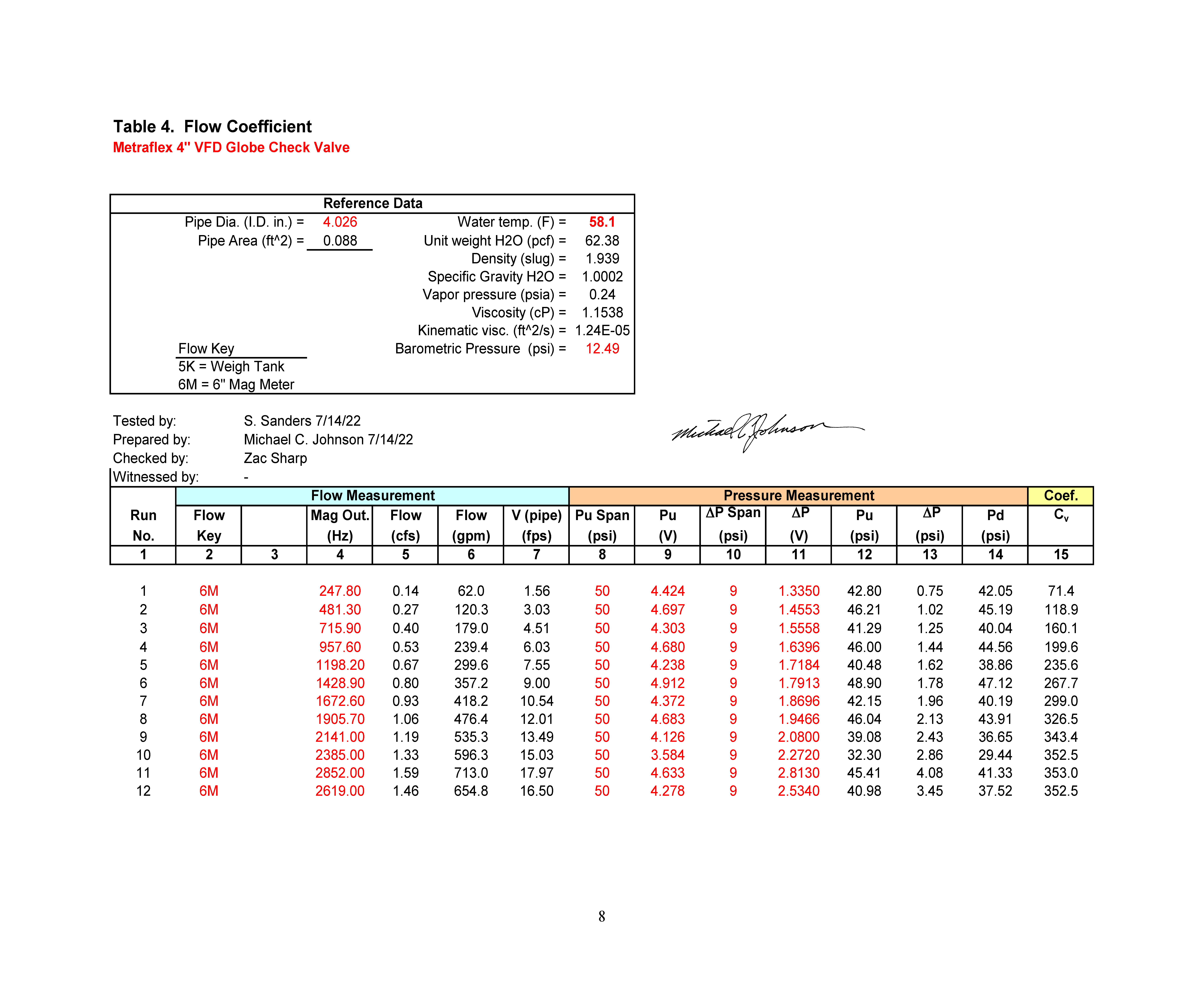

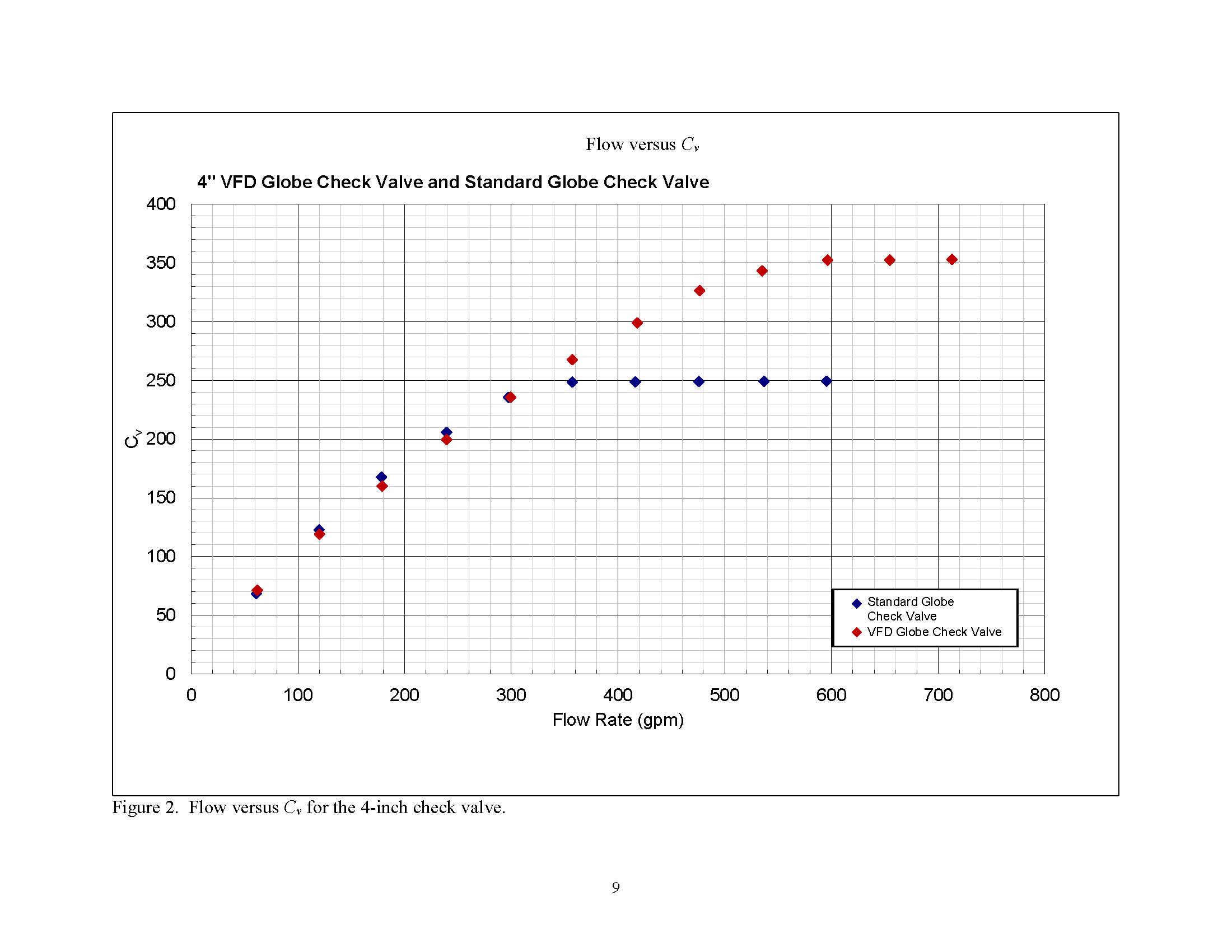

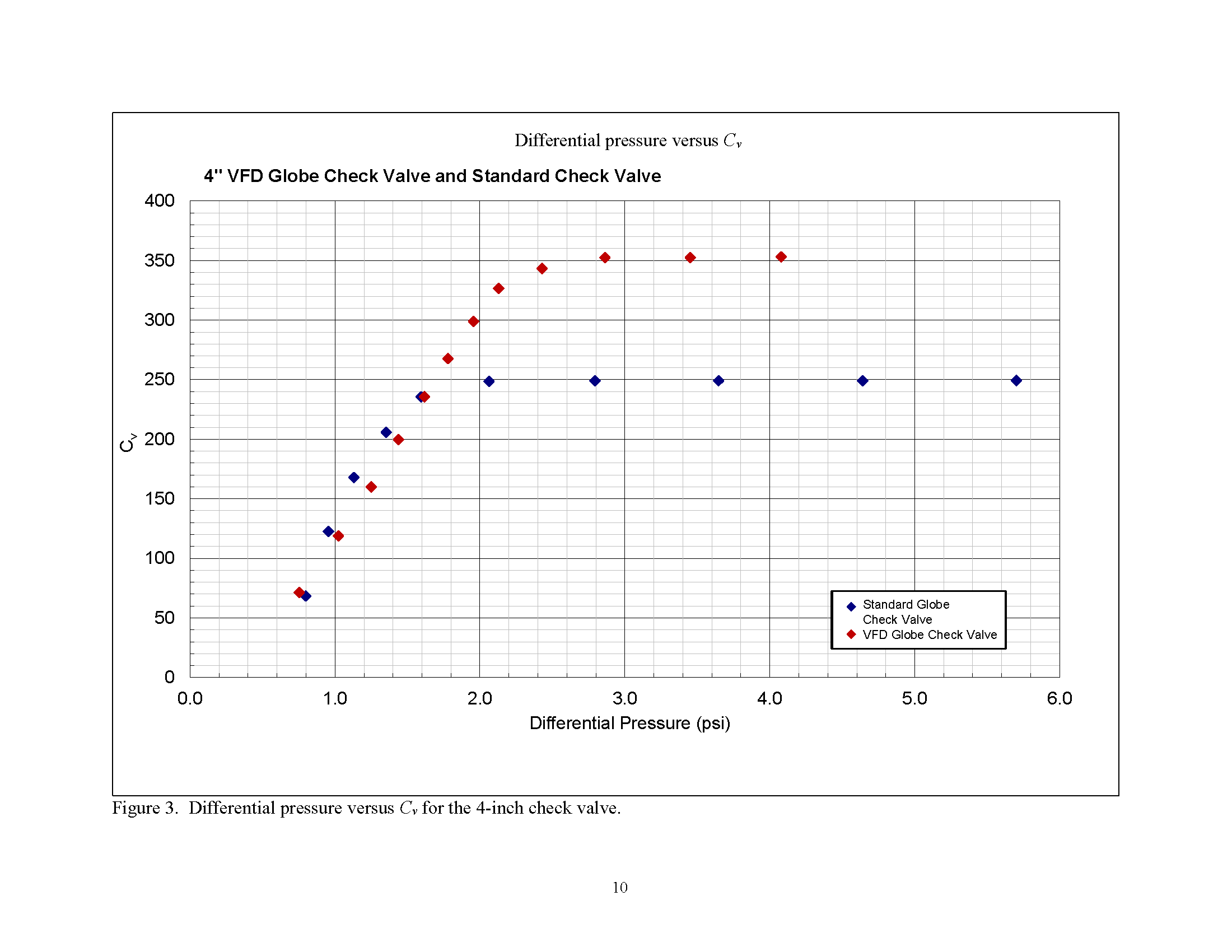

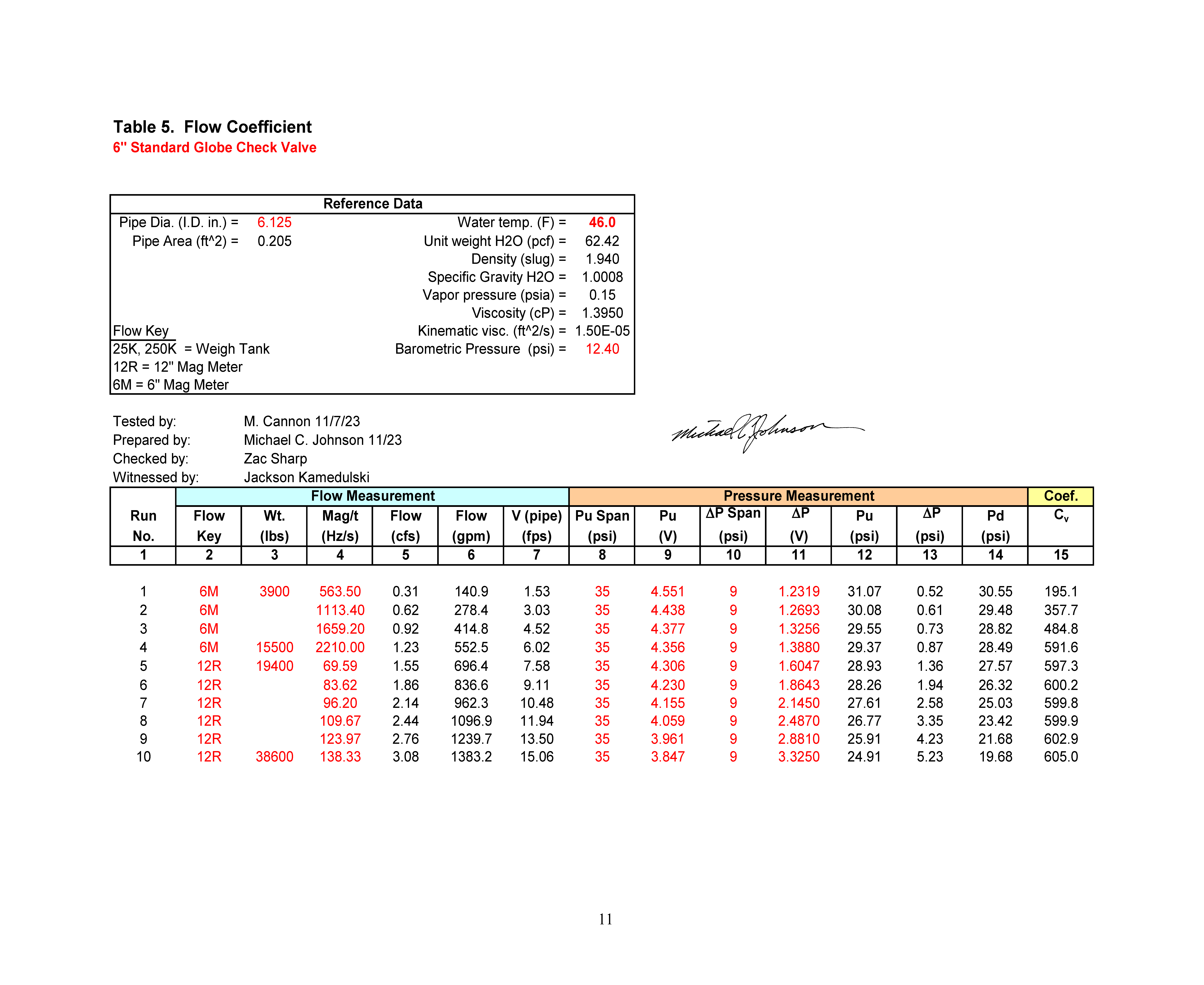

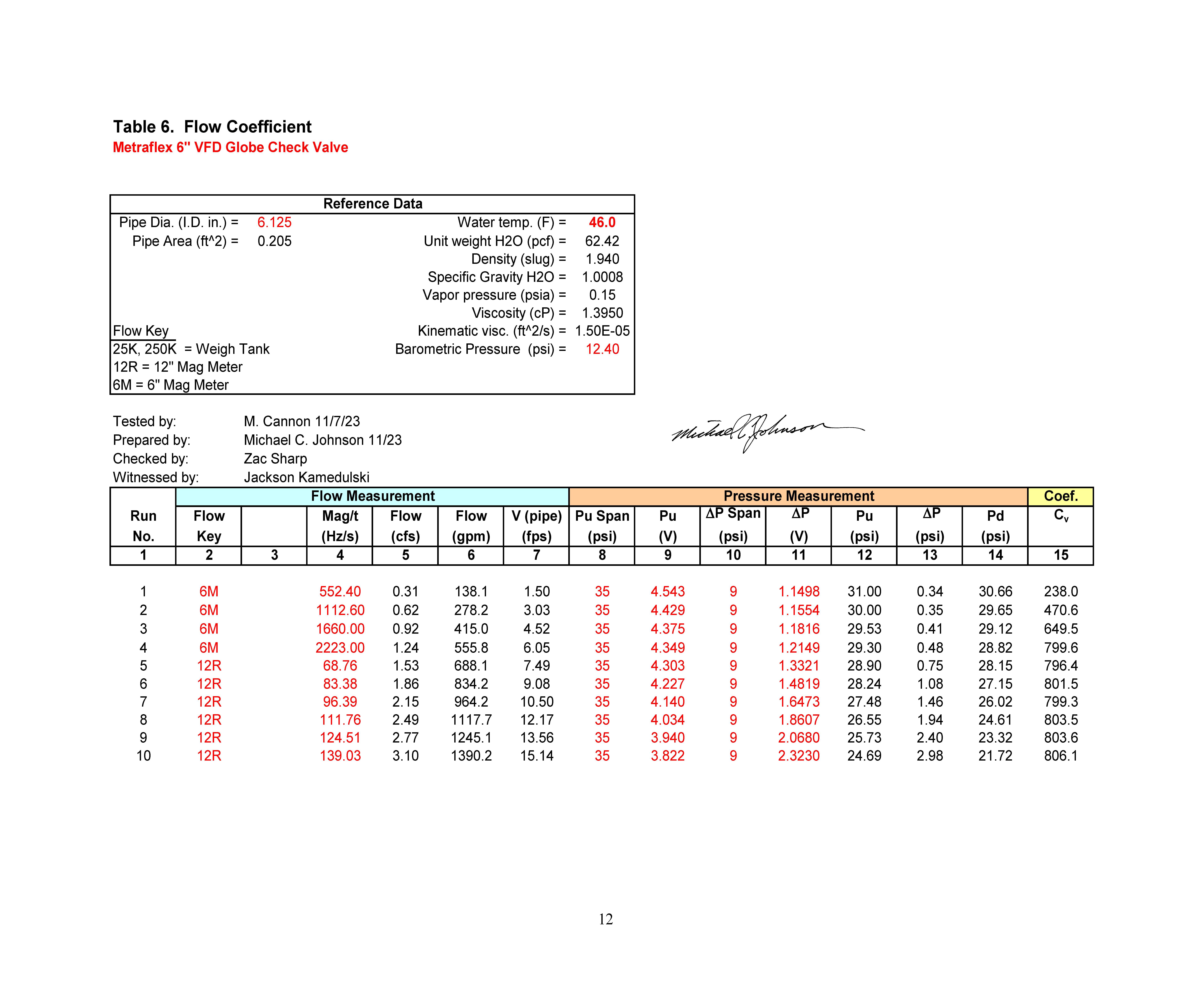

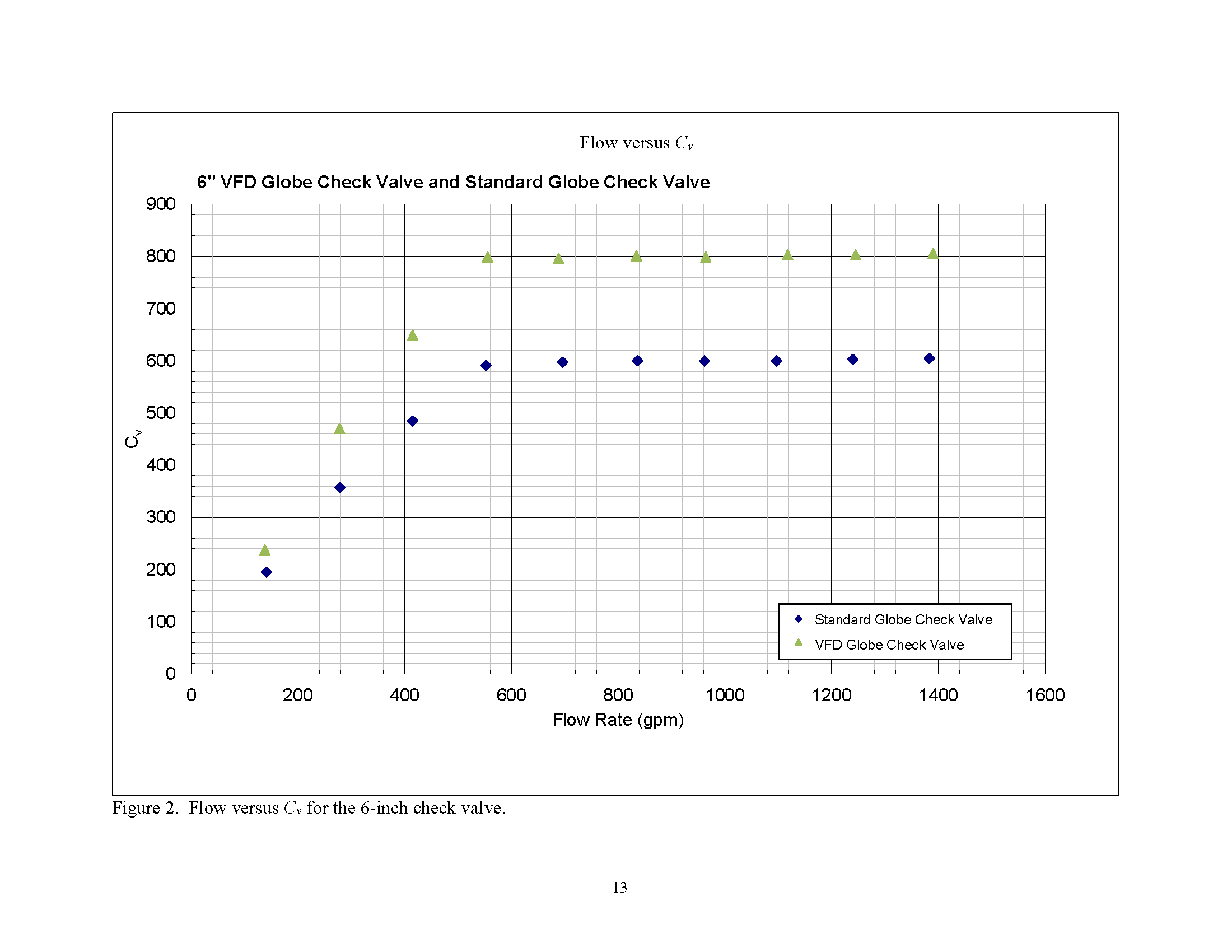

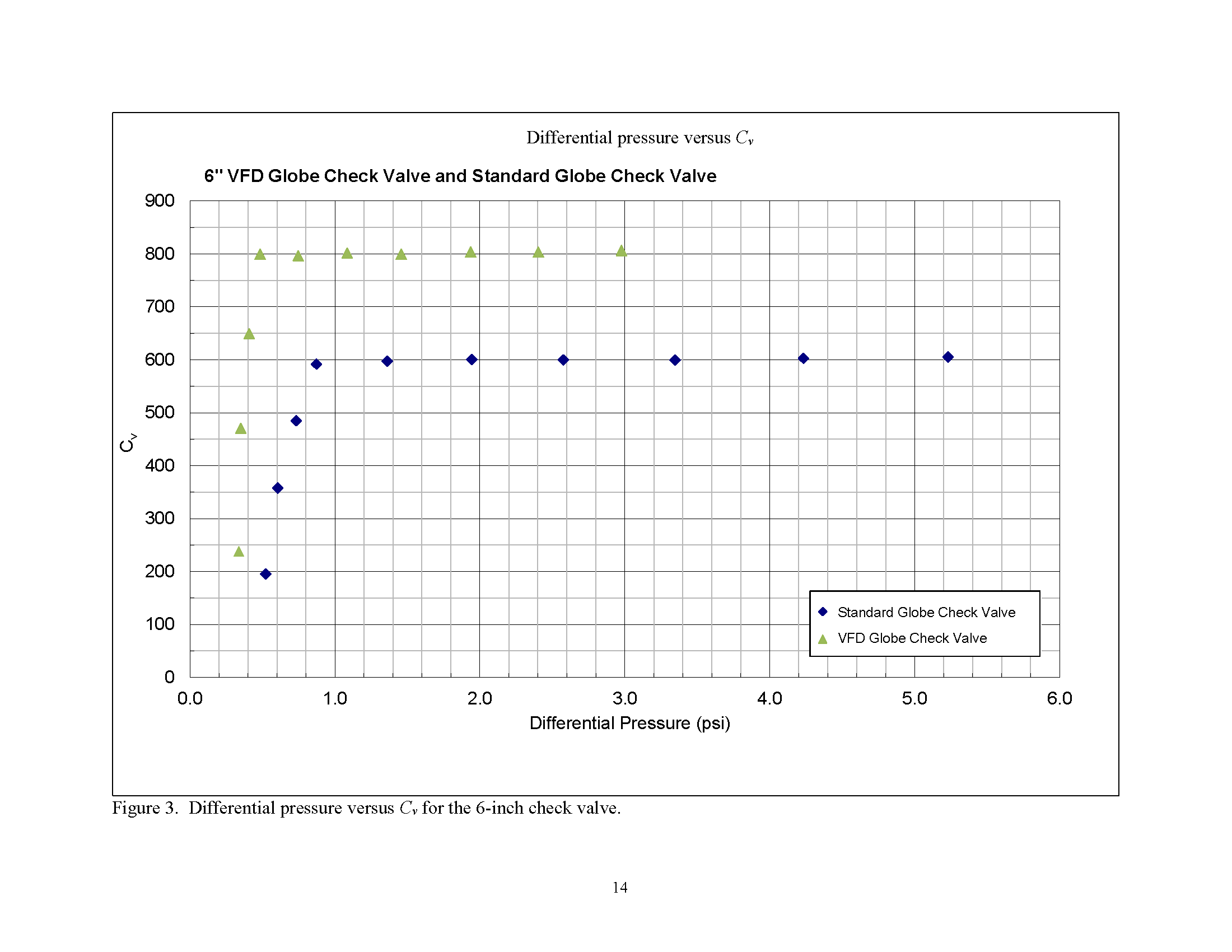

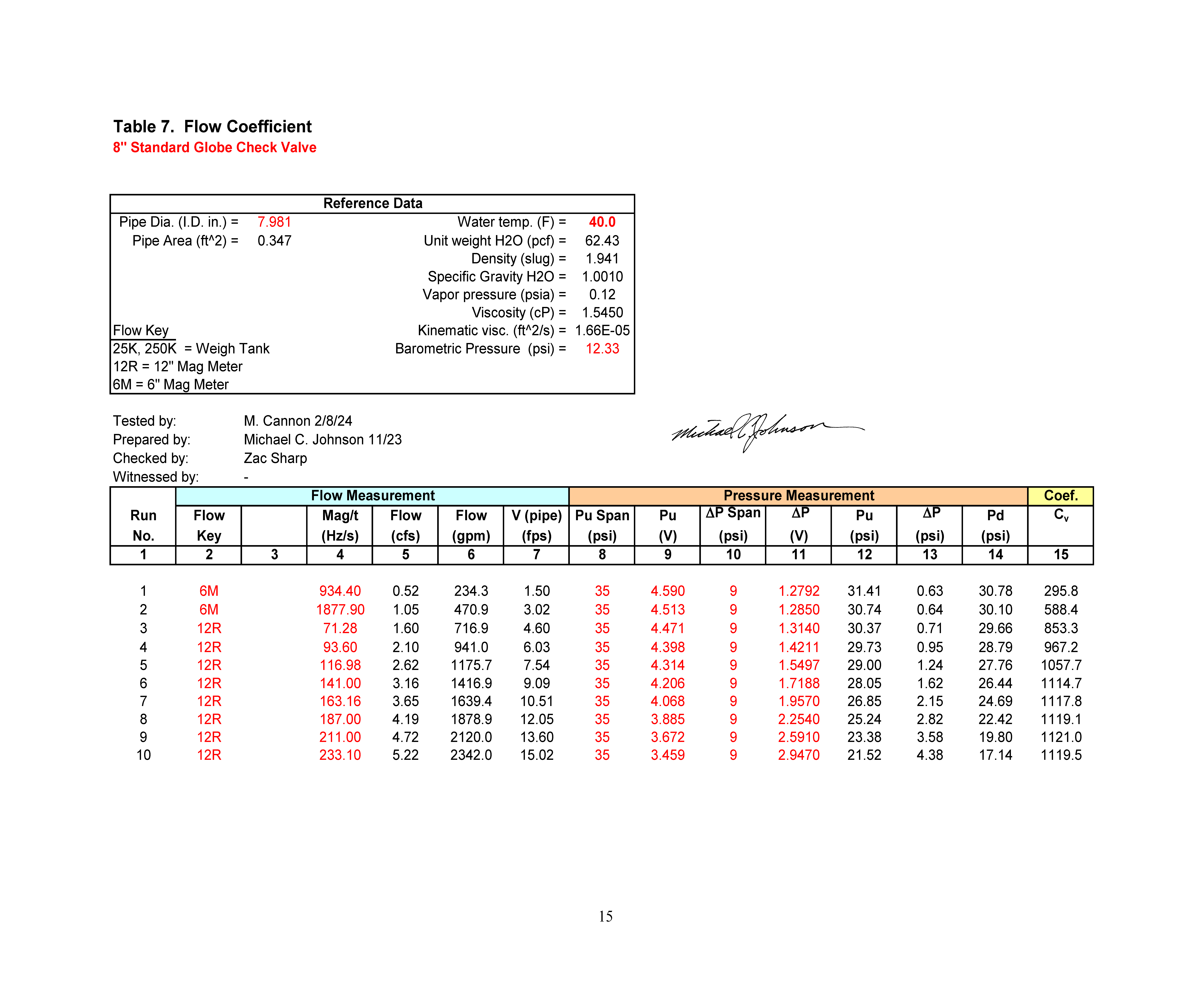

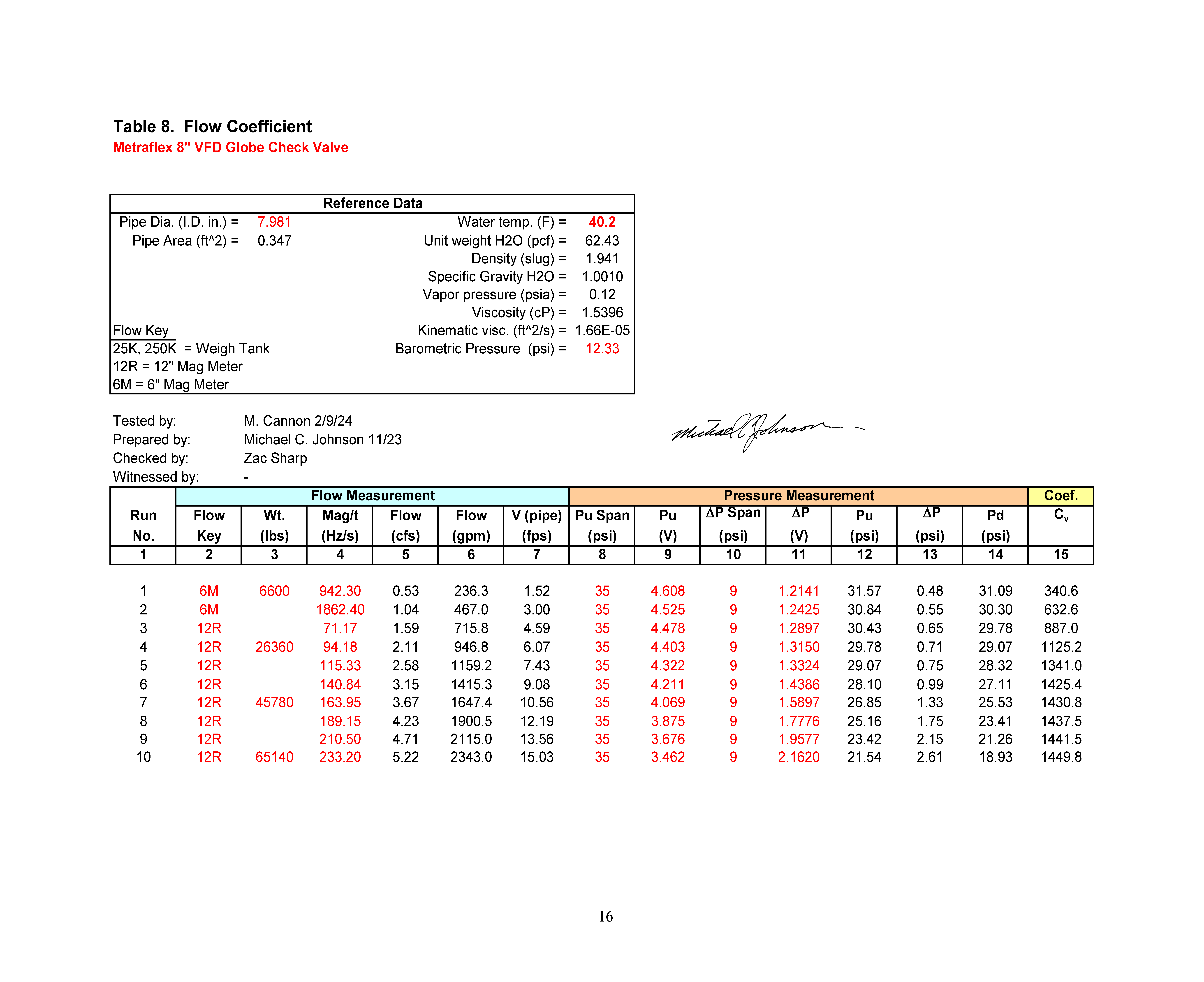

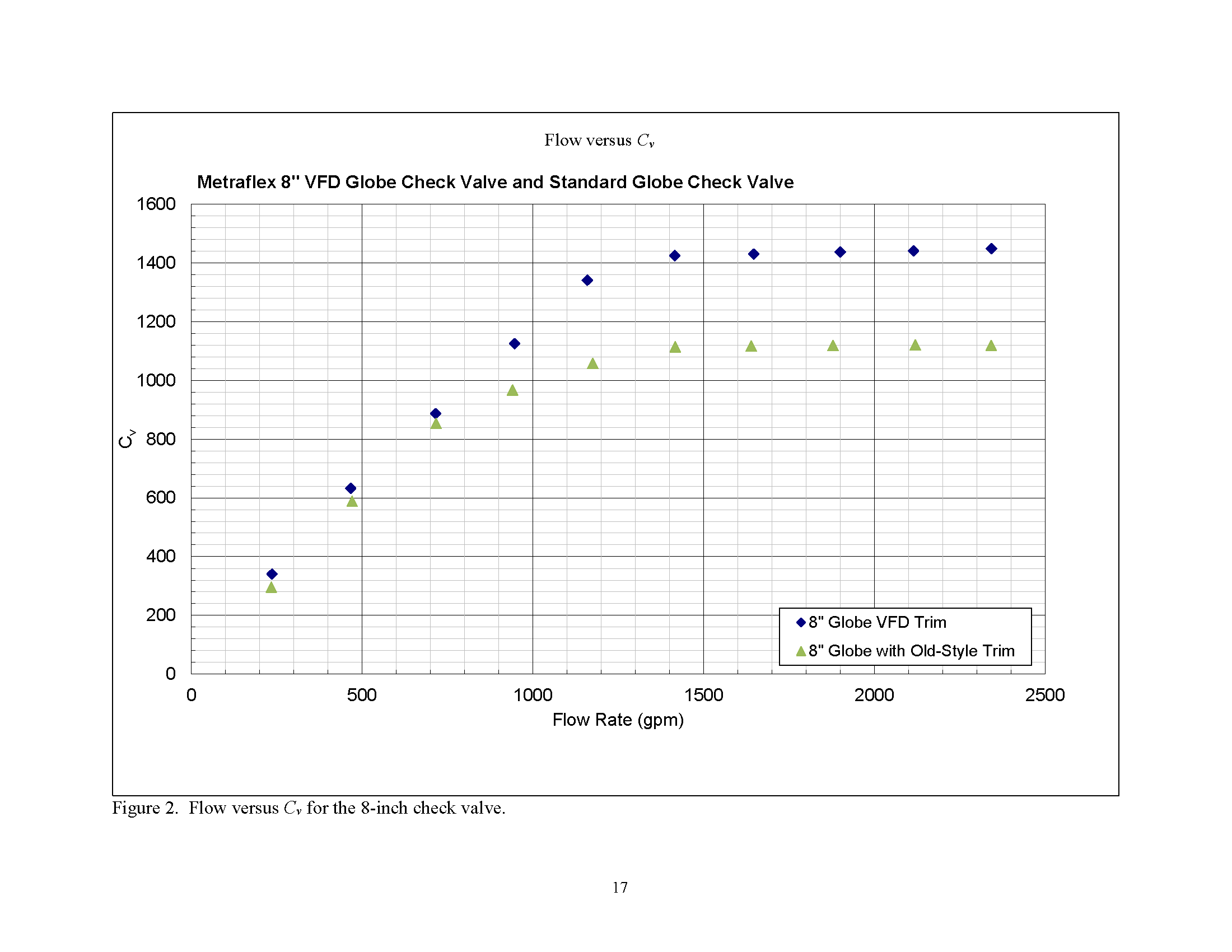

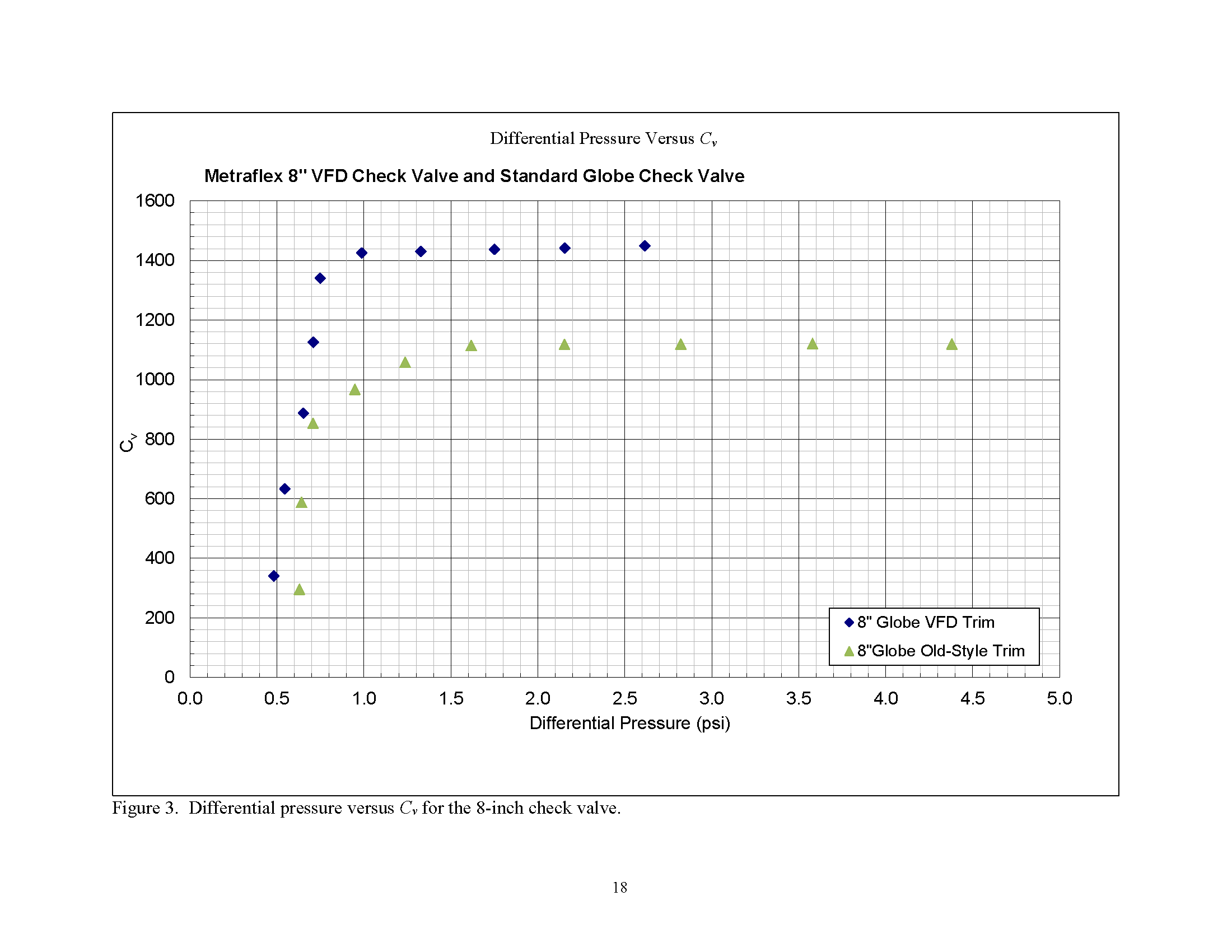

Flow Coefficient performance tests were conducted at the Utah Water Research Laboratory (UWRL) on a 3, 4, 6 & 8-inch standard globe check valves manufactured by Metraflex. The valve was provided with two disc configurations and two springs; the original disc, guide and spring and a new disc, guide and spring (VFD Check Valve). The intent of the testing was to quantify the valve’s discharge capacity for the two different disc configurations over a wide range of flow conditions with the pressure loss and flow measured and flow coefficients determined. The work was authorized by Metraflex with the intent to pay using corporate credit card and was done in accordance with the ANSI/ISA 75.02.01-2008 Control Valve Capacity Test Procedures standard with slight modifications in order to characterize the valve’s performance over a wide flow range.

EXPERIMENTAL PROGRAM

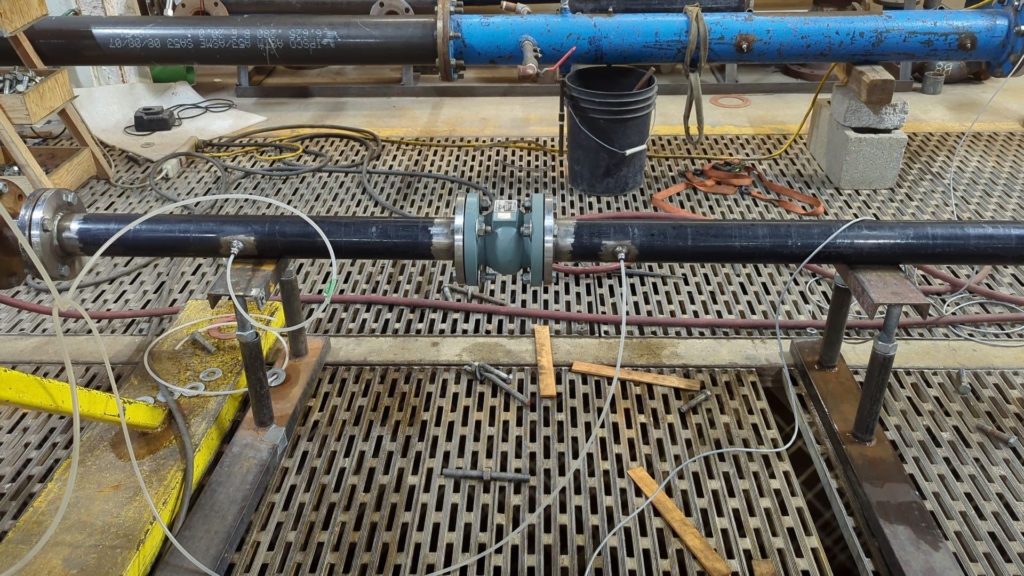

The valve under test was installed in a test line with approximately 20 diameters of straight approach piping to provide uniform flow at the inlet of the valve. There were approximately 10 diameters of straight pipe downstream from the valve. Pressure taps were located two pipe diameters upstream from the valve and six pipe diameters downstream from the valve. Flow was supplied using a 100-horsepower pump. Figure 1 shows the test setup.